Owner: Baldwin Real Estate Development Corp | Location: Canandaigua, NY

NYSERDA Buildings of Excellence Early-Design and Demonstration Awardee

How CreekView Apartments is Reducing Carbon Emissions

CreekView Apartments Phase II is a 72 unit housing project in Canandaigua, NY containing a mix of 1-, 2-, and 3-bedroom units. Continuing the Passive House certified Phase I completed in 2019, CreekView Phase II will reach Net-Zero energy utilizing Passive House Standards while reducing carbon emissions. The project is built on a park-like, 30-acre parcel of land in Canandaigua, NY. In addition to access to ample green space, residents benefit from close proximity to child and health care services, grocery stores and retail centers, sports and entertainment options, a community college, and high-quality public schools.

The CreekView Phase II project is developed by Baldwin Real Estate, built by DiMarco Constructors, designed by SWBR, MEP Engineering by EC4B, with Passive House Consulting and Verification by Sustainable Comfort, Inc. CreekView Phase II continues a commitment by Baldwin to reduce carbon emissions throughout their building portfolio. Their design of 8-plex housing style has evolved over the past 10 years from a gas heated LEED project at Riverknoll in 2015, to the Phius Certified CreekView Phase I in 2019, to the innovative Net-Zero energy design of CreekView Phase II.

Eliminating carbon emissions in housing projects is imperative to reduce the impact of climate change. A comprehensive approach to low carbon housing provides:

Lower environmental impact

Maximum incentives and tax credits

Meeting low carbon policies

Lower operating & maintenance cost

More comfortable homes

Healthier indoor air quality

Lower refrigerant leakage and lower Global Warming Potential (GWP) refrigerants

NYSERDA Support

Through the use of NYSERDA Buildings of Excellence Early Stage Design funds, the project has compared the embodied carbon and operational carbon of the past 3 projects showing a dedicated approach to reducing carbon emissions. NYSERDA awards include:

Buildings of Excellence Demonstration: $1,000,000

Early Design Support: $100,000

New Construction-Housing: $288,000

NY-Sun: $84,750 ($0.25/W)

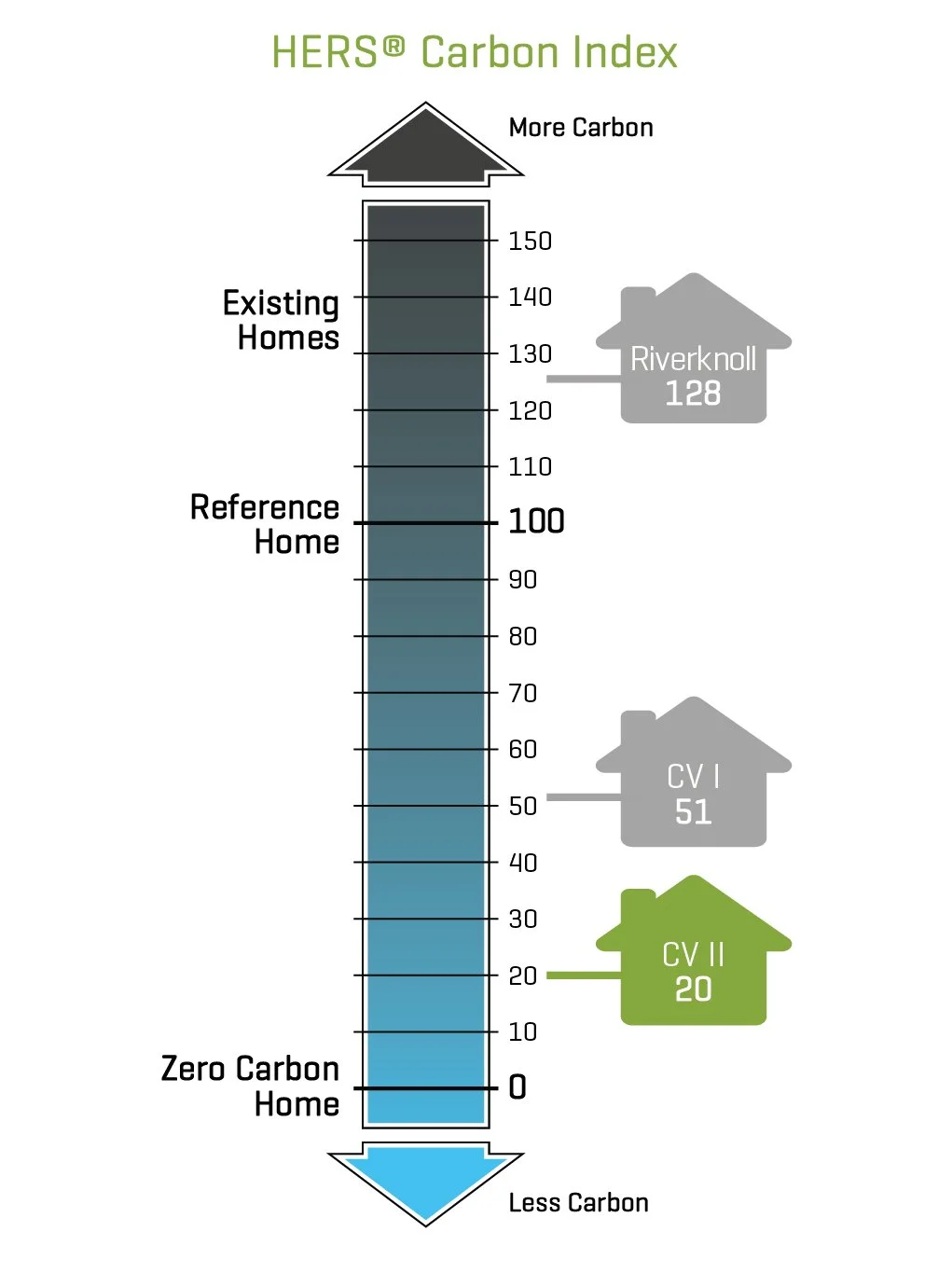

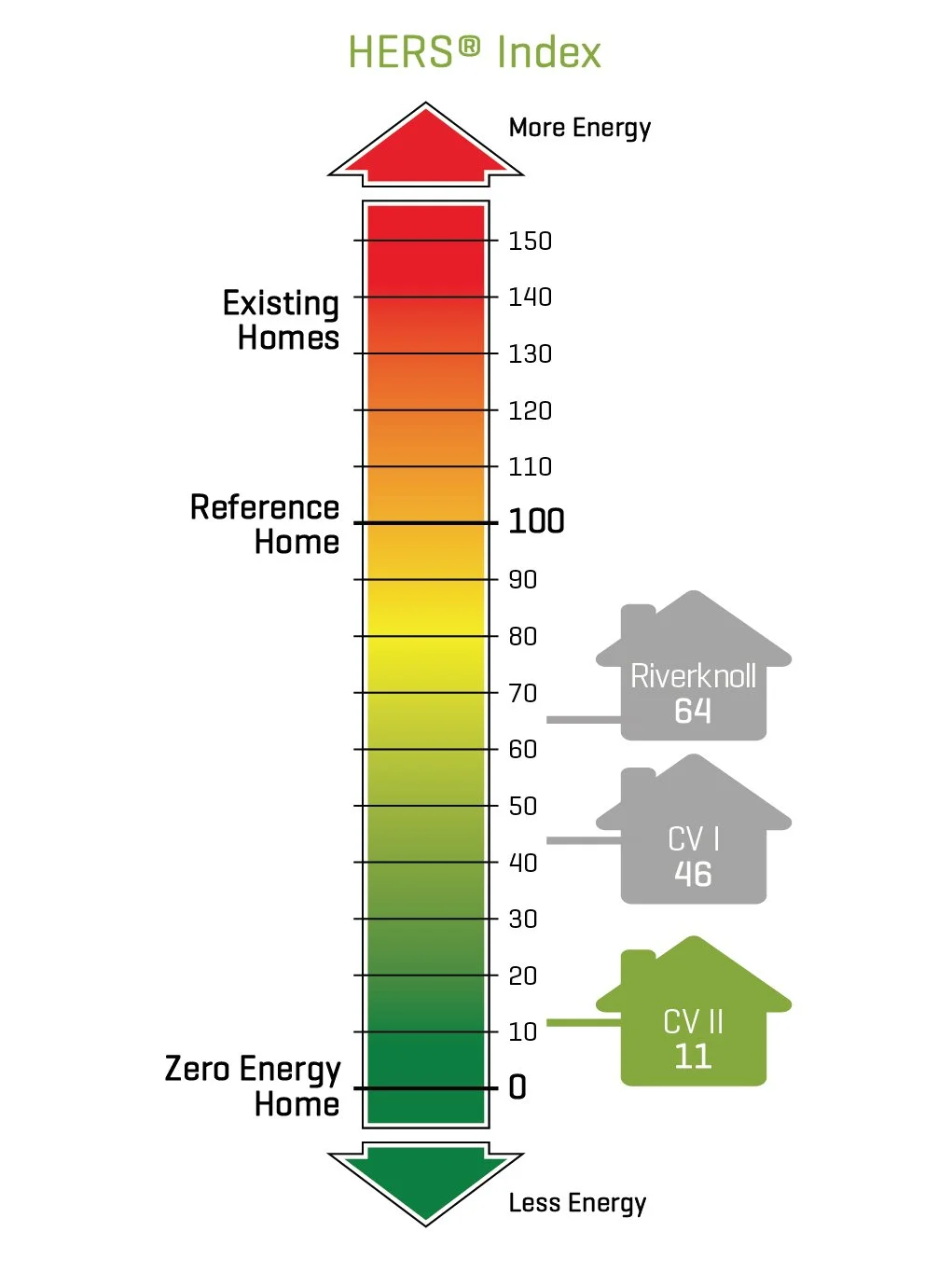

Measuring Carbon Emissions

Carbon emissions were compared and measured over the past three projects using the HERS Carbon Index to measure operational carbon emissions caused by the ongoing energy use and fossil fuel use of the property. At CreekView Phase II, the team has successfully reduced operational carbon emissions by 84% compared to Riverknoll and 66% compared to CreekView Phase I by focusing on Passive House insulation and air tightness, all electric ground source heat pumps, solar PV, and a focus on healthy indoor materials. Embodied carbon was measured for each site using the BEAM embodied carbon estimating tool to show the comparison of embodied vs. operational carbon emissions. Refrigerant leakage emissions are expected to be significantly reduced with CreekView Phase II Ground Source Heat Pump systems compared to Air Source where long refrigerant lines are shown to leak at a rate of 3% per year on average.

Technical Details

| Property | Riverknoll | CreekView Phase I | CreekView Phase II |

|---|---|---|---|

| Location | Baldwinsville, NY | Canandaigua, NY | Canandaigua, NY |

| Year Completed | 2015 | 2019 | 2026 |

| Wall | R 21 total. Batt plus advanced framing | R 37 total. R 21 cavity plus R 19 ci | R 37 total. R 21 cavity plus R 19 ci |

| Windows | U 0.3, SHGC 0.26. Double hung | U 0.15, SHGC 0.33. Casements | U 0.15, SHGC 0.33. Casements |

| Air Barrier | Taped Tyvek | Fluid applied air barriers | Fluid applied air barriers |

| Roof | R 38 batts | R 59 to 78 blown | R 59 to 78 blown cellulose |

| Slab | R 10 perimeter | R 20 under slab | R 20 under slab |

| Heating and Cooling | Gas furnaces, SEER AC | Ductless mini splits. 10 HSPF, 18 SEER | GSHP to ducted air handler. 3.3 COP |

| Ventilation | Exhaust only | Unitary ERV. 77% eff | Shared ERV. 77% eff |

| Hot Water | 0.67 EF gas storage | 1 BR gas. 2 to 3 BR electric resistance | Central GSHP. 3.3 COP |

| Appliances | Energy Star appliances | Energy Star appliances | Energy Star appliances |

| Lighting | LED and CFL lighting | LED lighting | LED lighting |

| Solar | - | - | 339 kW rooftop PV |

| EV Charging | - | - | (6) EV stations plus (36) EV capable |

Learn more about this comparison study by checking out the full NYSERDA Early Stage Design Report here:

Passive House Building Standard

CreekView Phase II has received Phius 2024 Source Zero Design Certification through Passive House Institute US (Phius). Passive House is the most rigorous green building standard in the nation and requires superior insulation and energy efficient HVAC and appliances. Phius-certified buildings typically use 40 to 60 percent less energy for heating and cooling than code-built homes. The standard also provides a framework for buildings of all types to maximize their efficiency while prioritizing cost-effective solutions. The required verification of insulation quality, air tightness, and ventilation effectiveness provides confirmed performance and quality.

To achieve Phius Zero Energy Targets, the CreekView Phase II project is utilizing all-electric mechanical systems including ground source heat pump systems for heating, cooling, and hot water heating, shared Energy Recovery Ventilation (ERV), and roof-mounted solar PV systems on each building.

Compared to the air source heat pumps at Phase I, the geothermal systems have lower maintenance costs related to filter changes and mini split head cleaning. There are also fewer pieces of equipment prone to failure due to the central mechanical systems. The owner pays all electric utilities on the project to receive the full benefit of the on-site solar PV systems.

The buildings are effectively air tight through the use of an exterior fluid-applied air barrier over consistent sheathing, with advanced insulation including 3.5 inches of exterior rigid insulation and blown-in cellulose attic insulation. The envelope is completed with continuous under-slab insulation and triple pane casement windows over fixed windows to provide air-tight performance. The efficient envelope and mechanical systems allow the building’s energy demand to be offset by the roof-mounted solar PV system.

Fig: 10 Year emissions performance of similar 72 unit projects at Riverknoll, CreekView I, and CreekViewII, plus 2 theoretical projects with low embodied carbon discussed below.

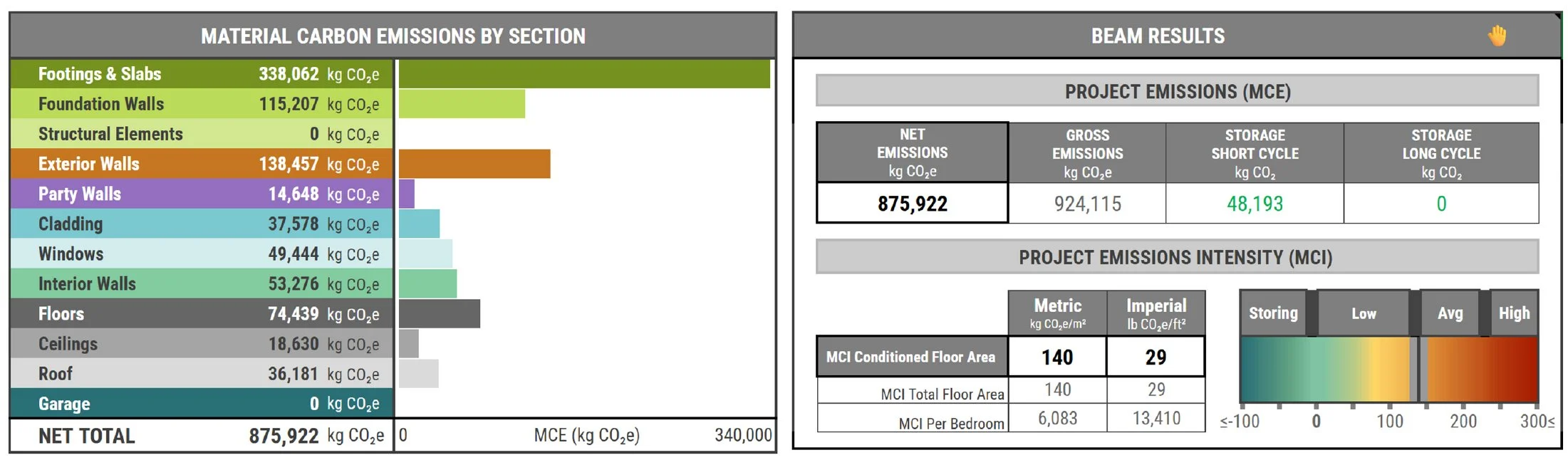

CreekView II Embodied Carbon

The embodied carbon was calculated for CreekView Phase II using the Building Emissions Accounting for Materials (BEAM) tool which shows low embodied carbon emissions compared to similar projects based on structure, enclosure, insulation, and finish selection.

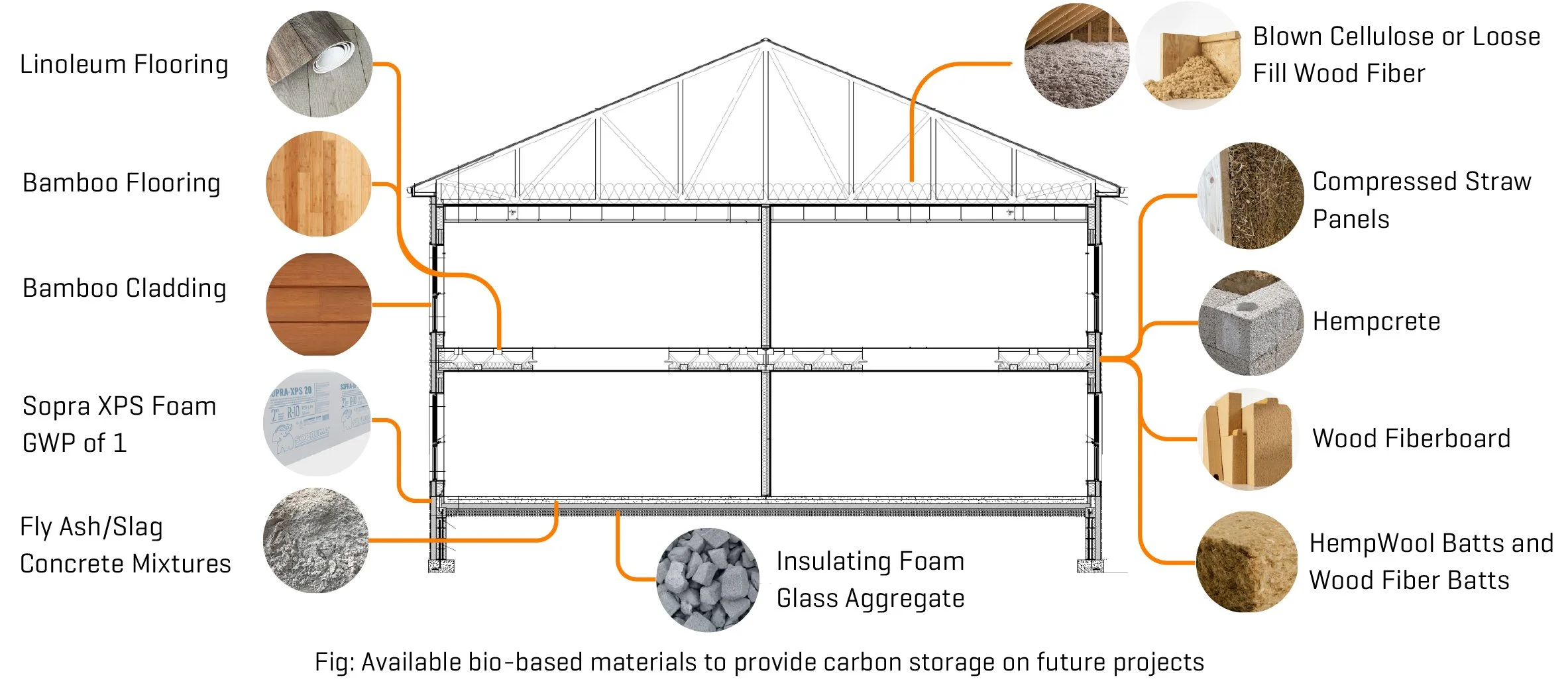

The Future of Bio-Based Materials

For future developments, the use of low carbon materials can serve to reduce the initial embodied carbon. A Low-Carbon Option was explored with readily available product replacements such as:

Swapping slab insulation to foam glass aggregate

Swapping exterior polyiso to wood fiberboard

Upgrading concrete mixtures to include >20% SCM

Swapping batt insulation for wood fiber batts

Using XPS with low GWP blowing agents

There are also several innovative techniques being developed to allow for deeper carbon storage using locally sourced bio-based alternatives that store carbon in building assemblies. The Bio-Based Option explored the use of materials such as manufactured insulated straw panels, which utilize agricultural waste products to store atmospheric carbon in the buildings for a long period of time. The impact of steel and concrete on building sector emissions is also very large. On this building type, using Supplementary Cementitious Materials (SCMs) such as fly ash and slag can greatly reduce emissions. Designing to remove concrete podiums or using mass timber frames instead of steel and concrete can greatly reduce overall emissions on larger building projects.

Fig: Available bio-based materials to provide carbon storage on future projects

Partners

Programs Achieved

See the full Early Design Study here:

https://www.nyserda.ny.gov/All-Programs/Multifamily-Buildings-of-Excellence/Early-Design-Support-Program/Creekview-Apartments